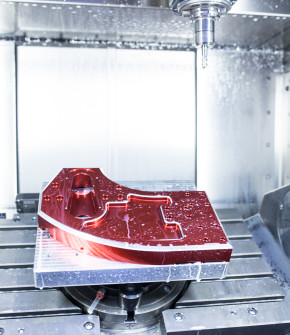

Precision manufacture with our own machinery

Rely on the precision machine production of individual components and entire assemblies at our own production plant. We have breadth and depth in experience manufacturing moulds, components for the automotive, aerospace, healthcare and optical industries, as well as electrodes and measuring and assembly devices. We have also made a number of non-standard components to the full satisfaction of our customers.

We machine plastics, aluminium alloys, coloured metals, steel (including stainless steel), titanium and other materials. We have our own design department and, in cooperation with our parent company SolidVision, we also provide precision 3D scanning of your existing components (and their conversion to 3D models) as well as additive production (3D printing).

Our department is equipped with powerful SolidCAM software.

We use the following modern machines to fulfil your demands:

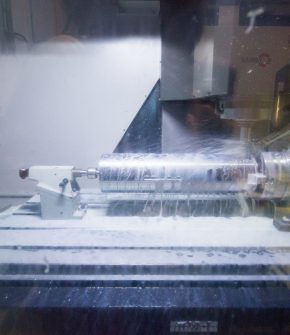

| CNC machining centre HERMLE C20 (5 axis) | |

| Working range of axis X/Y/Z [mm] | 600/450/450 |

| Axis A [°] | ±115 |

| Axis C [°] | 360 |

| Max. workpiece dimensions for 5-axis machining (larger parts to be consulted); Axis X/Y/Z [mm] | cca 300/300/200 |

| Maximum workpiece weight [kg] | 300 |

| Spindle | IS040 |

| Spindle [rpm] | 18000 |

| Tool magazine [pcs] | 30 |

| Machined materials | steel, aluminium, stainless, plastic, titanium |

| Control system | Heidenhain iTNC530 |

| Program creation | SolidCAM (3D, 5 axis continuously) |

| CNC – machining centre HERMLE C250 (5 axis) | |

| Working range of axis X/Y/Z [mm] | 600/550/450 |

| Axis A [°] | +/-115 |

| Axis C [°] | 360 |

| Max. workpiece dimensions for 5-axis machining (larger parts to be consulted); Axis X/Y/Z [mm] | d360 |

| Maximum workpiece weight [kg] | 300 |

| Spindle | ISO40 |

| Spindle [rpm] | 15000 |

| Tool magazine [pcs] | 30 |

| Machined materials | steel, aluminium, stainless, plastic, titanium |

| Control system | Heidenhain TNC 640 |

| Program creation | SolidCAM (3D, 5 os souvisle) |

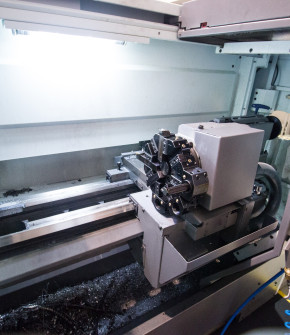

| CNC – centre lathe Pinacho ST-225 | |

| Working range – swing clearance [mm] | 450 |

| Swing over cross-slide [mm] | 260 |

| Centre-to-centre distance [mm] | 1000 |

| Spindle – chuck [mm] | 250 |

| Spindle bore [mm] | 65 |

| Maximum speed | 3000 |

| Tool head | 8 positions with cross-section 25×25 |

| Control system | Siemens 828D |

| Tailstock with loose centres | Yes |

| Work rest + faceplate | fixed and movable work rest + faceplate |

| Machined materials | steel, aluminium, stainless, plastic |

| CNC - machining centre DMG CLX 450 4V | |

| Working range – swing clearance [mm] | 650 |

| Swing over cross-slide [mm] | 465 |

| Centre-to-centre distance [mm] | 600 |

| Spindle – chuck [mm] | 315 |

| Spindle bore [mm] | 80 |

| Maximum speed | 4000 |

| Tool head | 12 positions with cross-section 25×25 |

| Control system | Siemens 840D SchopTurn |

| Tailstock with loose centres | Yes, hydraulic |

| Work rest + faceplate | No |

| Machined materials | steel, aluminium, stainless, plastic |

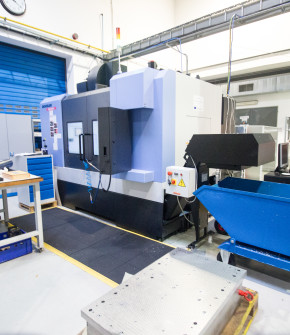

| CNC milling centre DOOSAN DNM 650 (3 axis) | |

| Working range of axis X/Y/Z [mm] | 1270/670/625 |

| Maximum spindle-table distance [mm] | 800 |

| Worktable dimensions [mm] | 1300 × 670 |

| Table load [kg] | 1000 |

| 4th axis with swing diameter over worktable [mm] | Yes, ⌀260 (with swing ⌀ over worktable 330) |

| Maximum spindle speed [RPM] | 12500 |

| Tool magazine [pcs] | 30 |

| Control system | DOOSAN FANUC i-series |

| Machined materials | steel, aluminium, stainless, plastic, titanium |

| Program creation | 2D on machine, 3D SolidCAM |

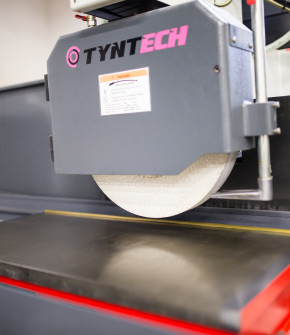

| Tool making knee and column machine TYNTECH TTM 4 HEV5-W | |

| Tailstock barrel bore with automatic feed [mm] | 127 |

| Machine feed of axes X, Y, Z | Yes |

| Worktable [mm] | 1500 × 300 |

| Maximum table load [kg] | 420 |

| Dividing device | BS2 with drive |

| Machined materials | steel, aluminium, stainless, plastic, cast iron |

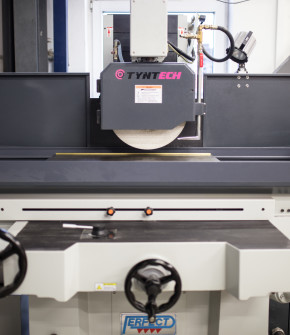

| Horizontal surface grinder PERFECT PFG-D4080AH | |

| Working range of axis X/Y [mm] | 800/400 |

| Maximum load [kg] | 400 |

| Max. grinding surface [mm] | 400 × 800 |

| Maximum spindle-table distance [mm] | 550 |

| Tool making centre lathe LINK LPT-1440GH | |

| Chuck diameter [mm] | 160 |

| Tool block min. for 4 tools or quick-acting tool system | Yes |

| Digital gauging for min. 2 axes | Yes |

| Turning diameter over bed [mm] | 360 |

| Turning diameter over carriage [mm] | 225 |

| Turning length [mm] | 1000 |

| Bed width [mm] | 190 |

| Spindle speed [RPM | 80-2000 |

| Spindle bore [mm] | 40 |

| Machined materials | steel, aluminium, stainless, plastic, titanium |

Would you like us to make anything for you? We will be happy to take care of it, just let us know.